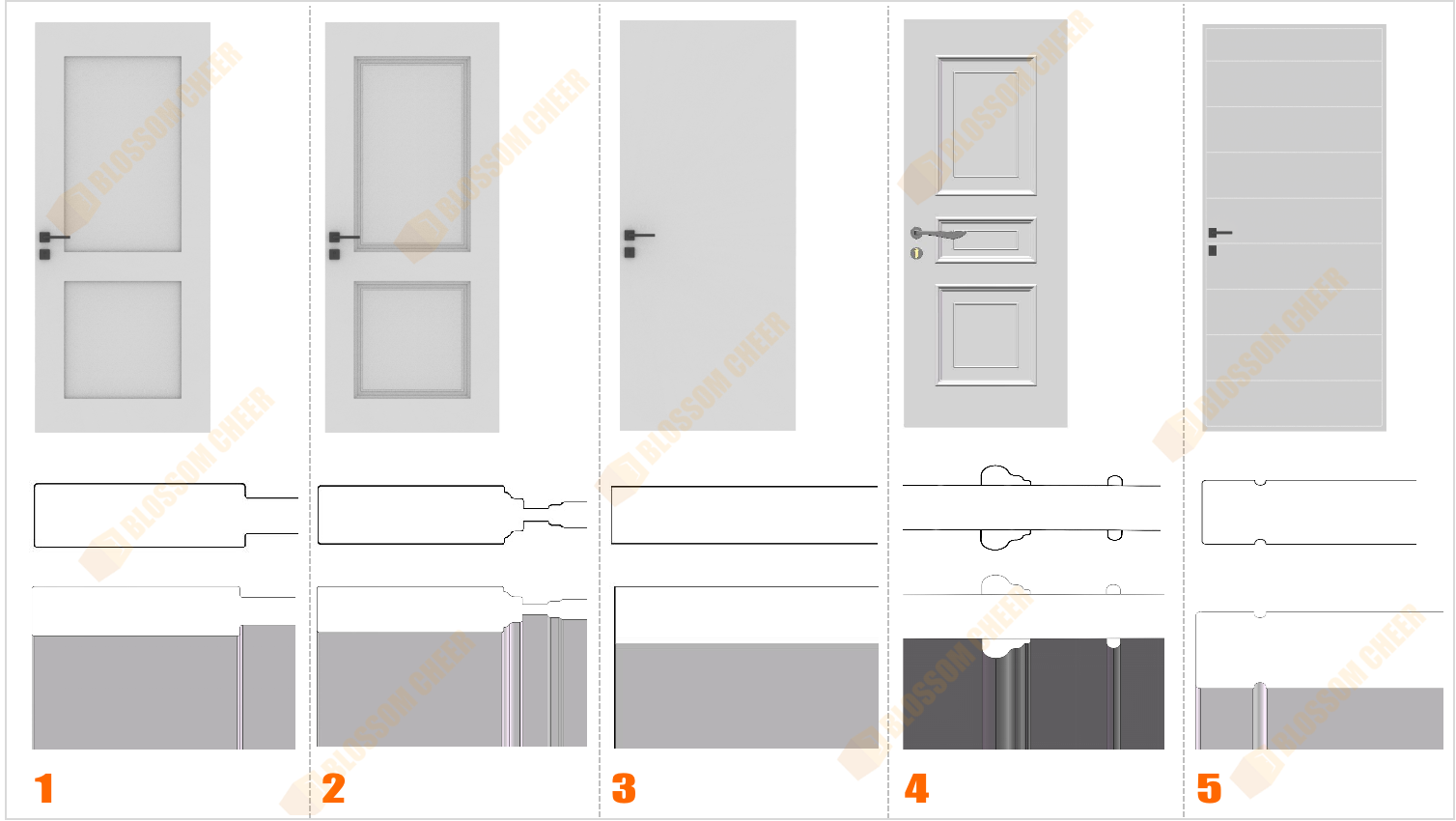

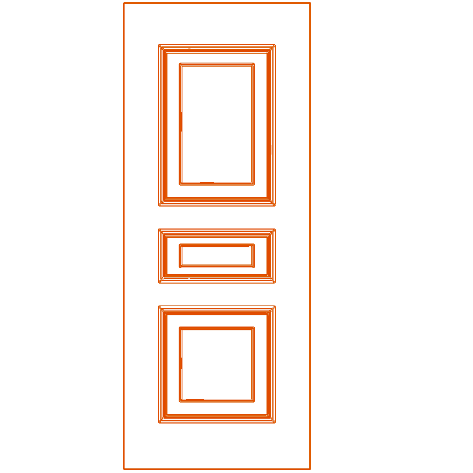

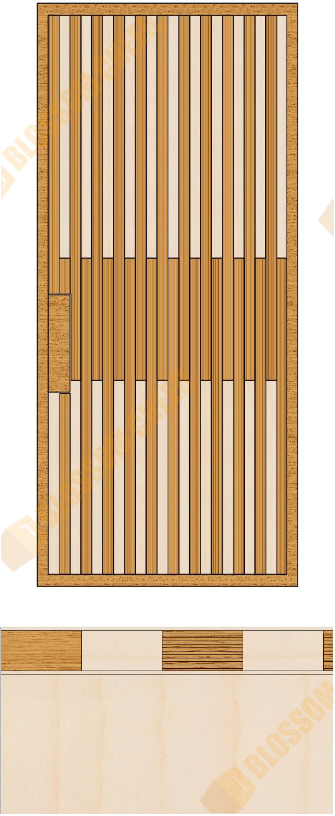

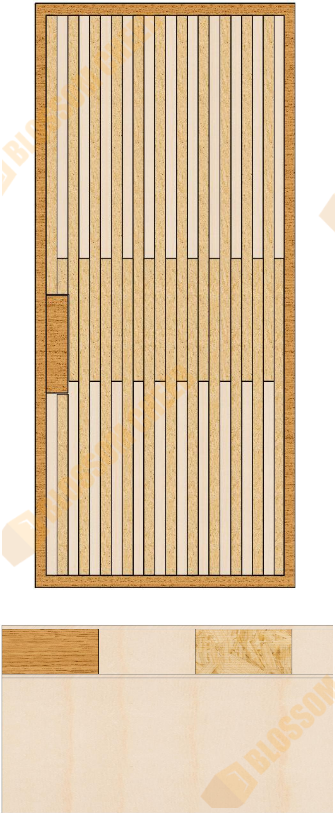

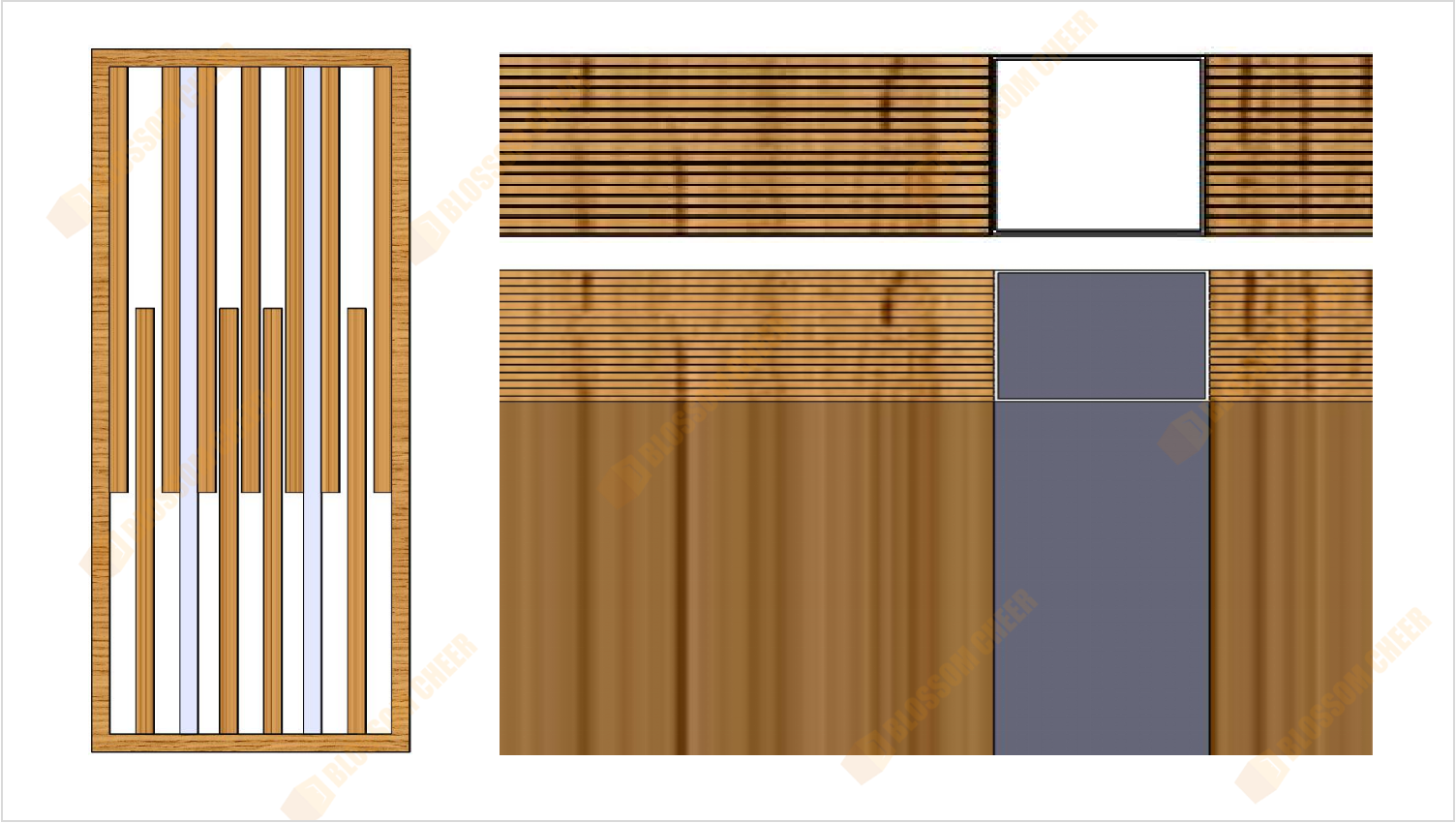

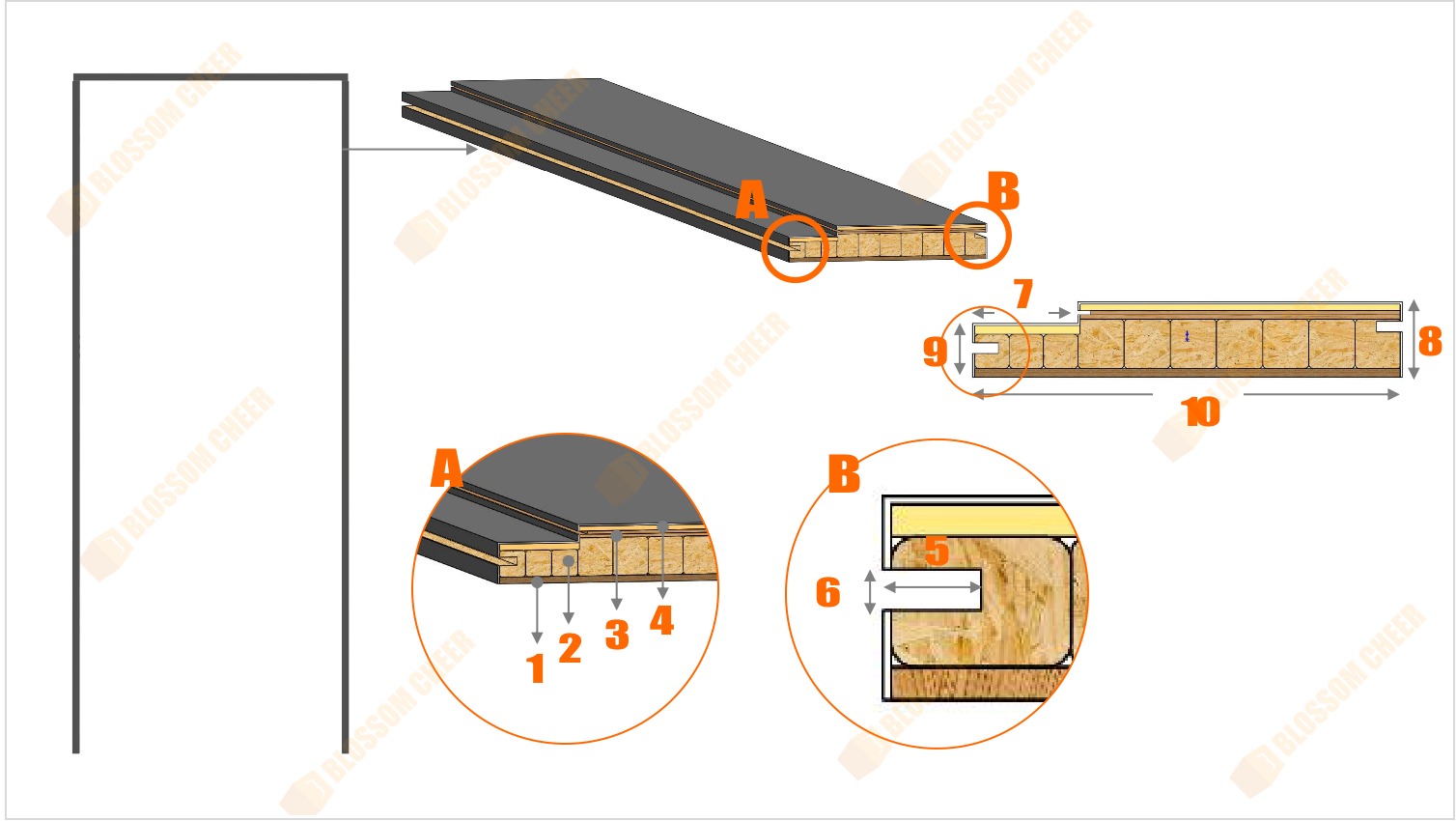

Composite Door Frame

Extreme cost performance, more than 85% of project select this type frame.

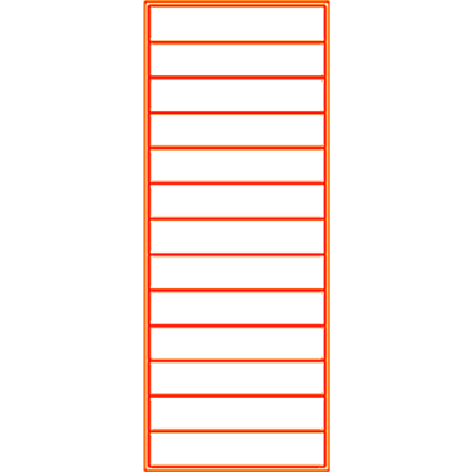

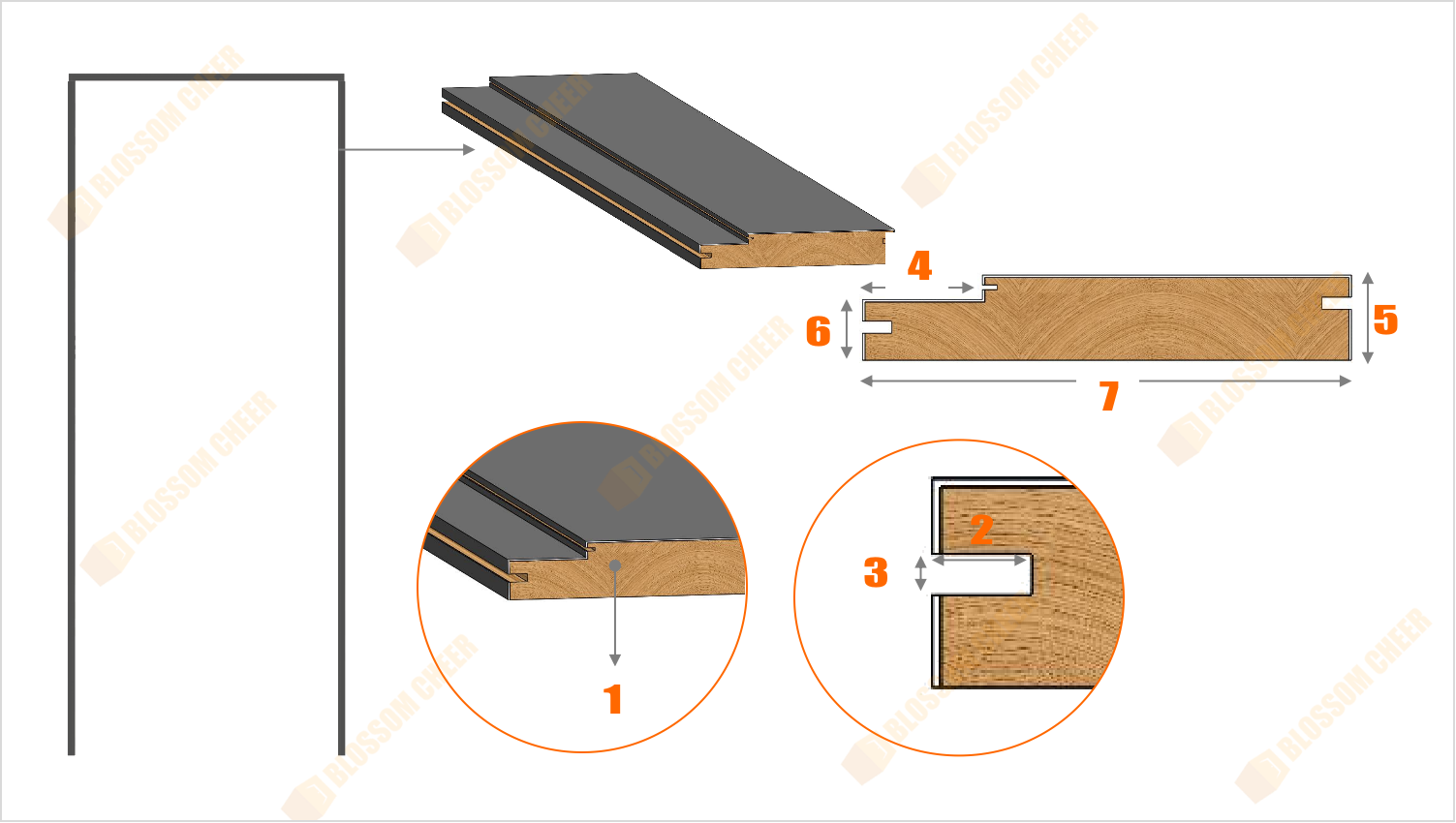

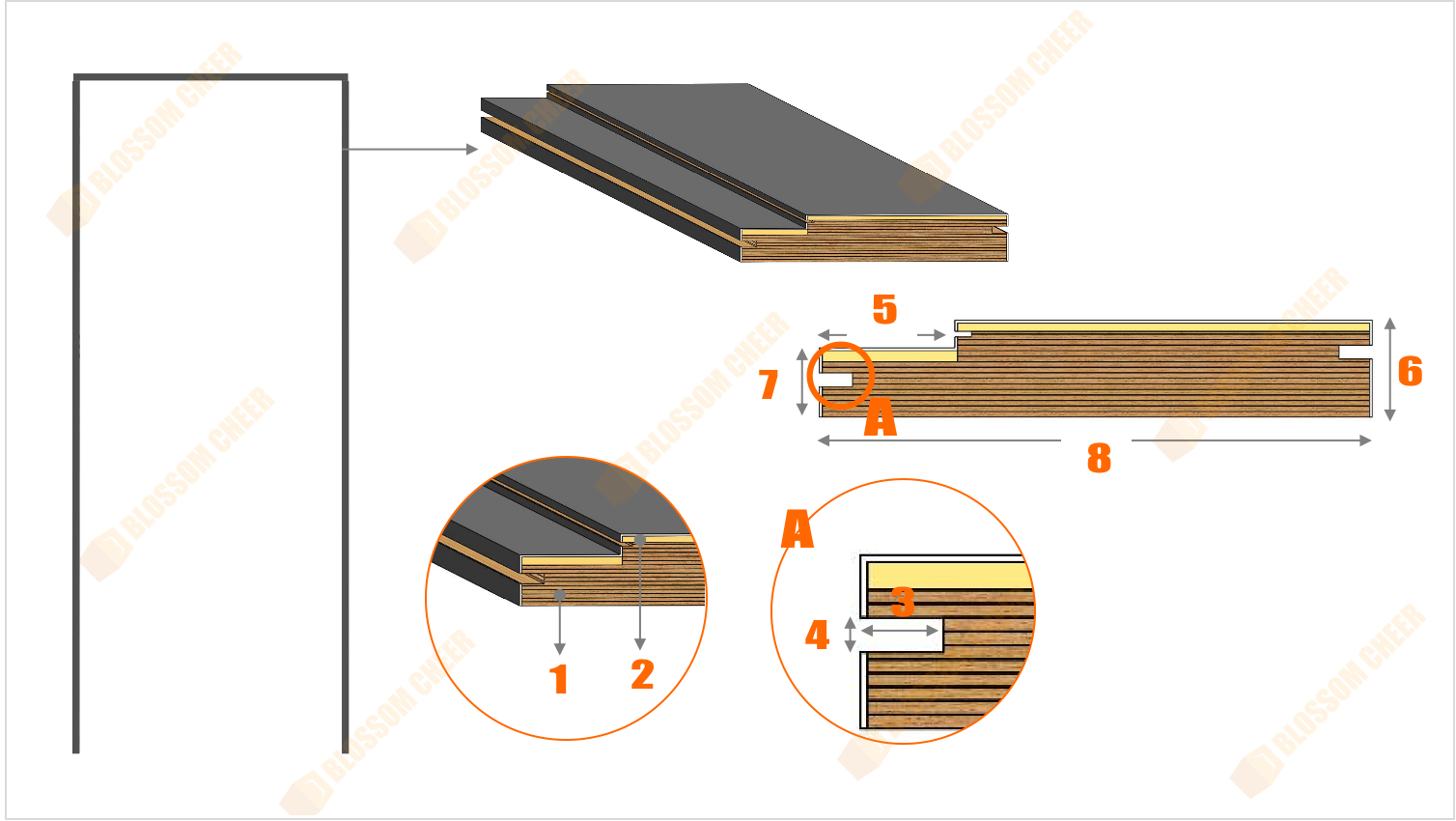

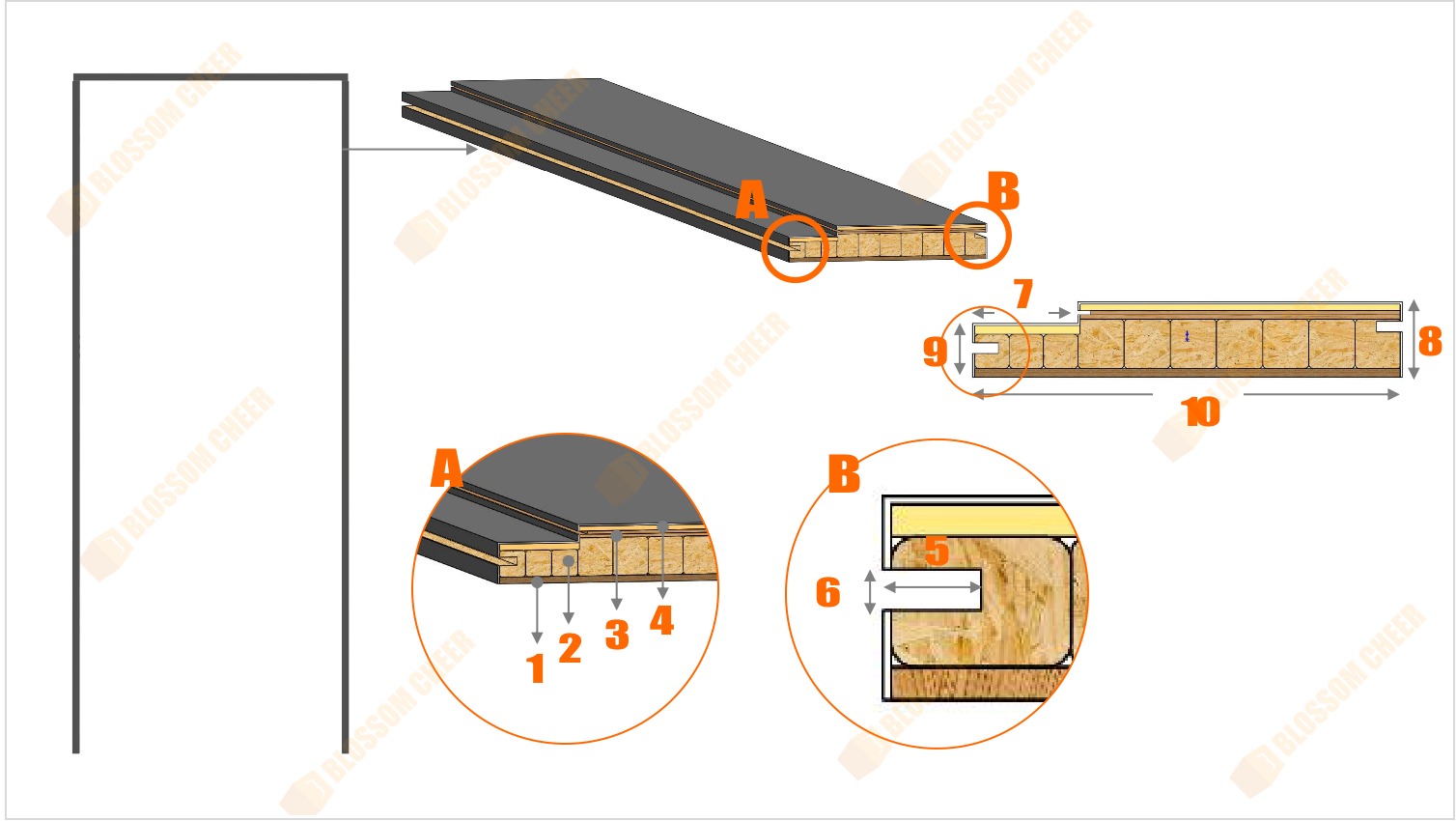

A、B

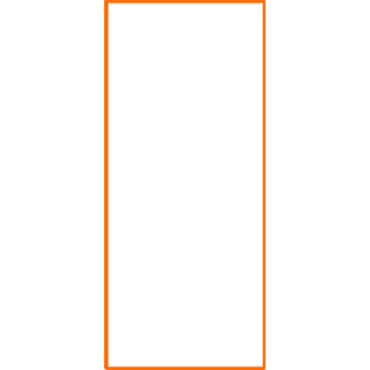

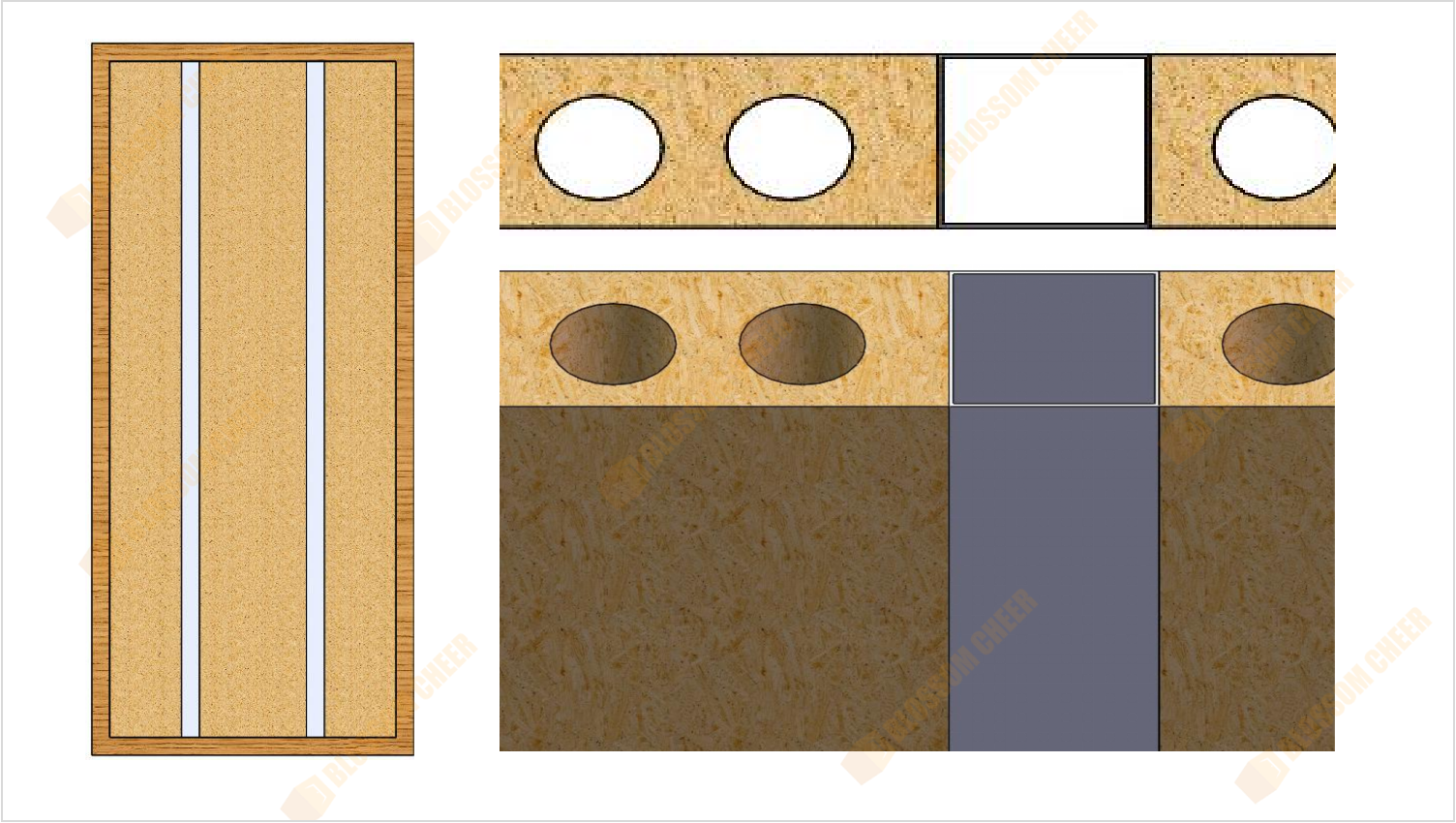

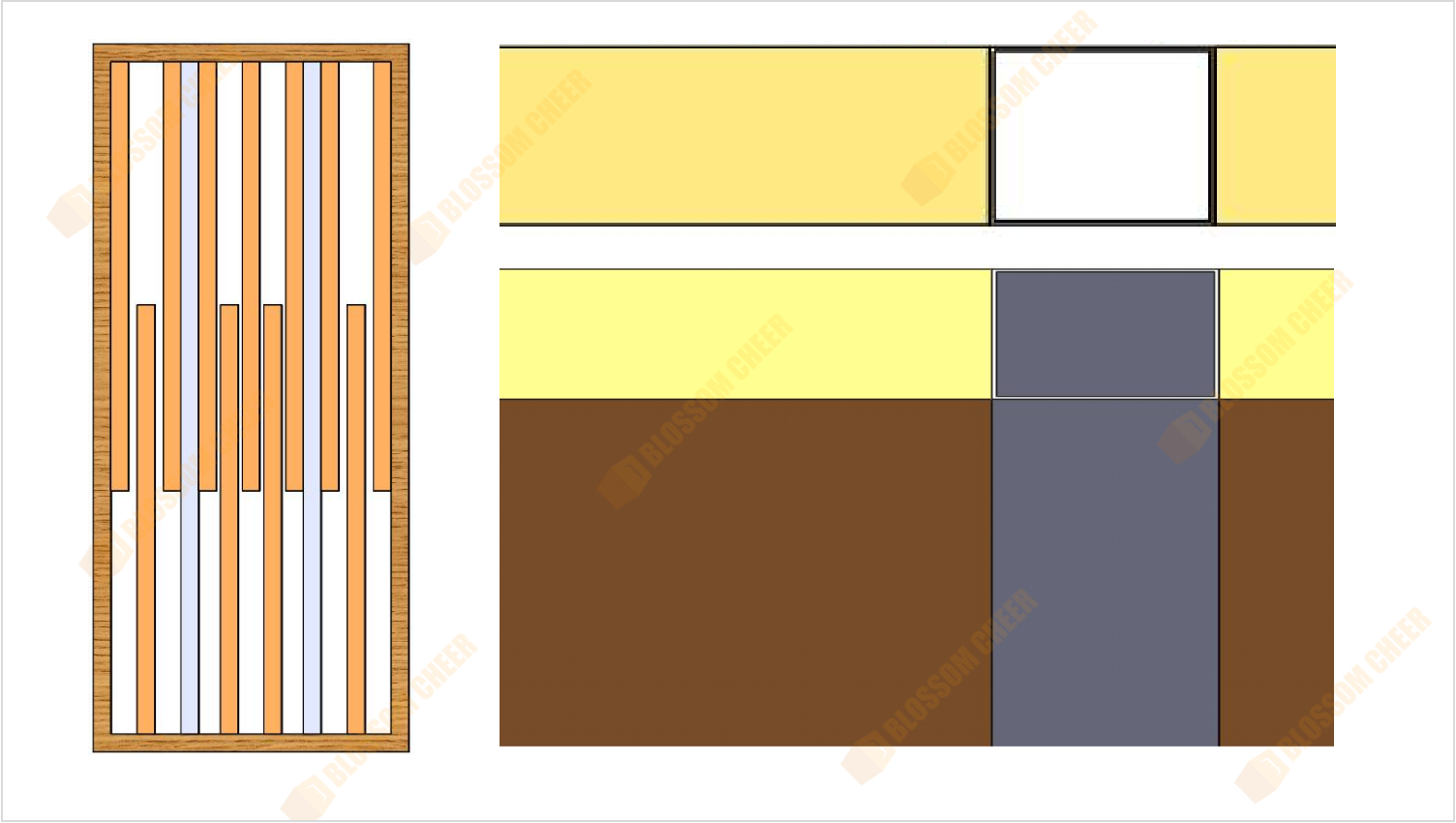

Enlarge the size and details of the gong groove (snap into the door sleeve), and explain it with parameters.

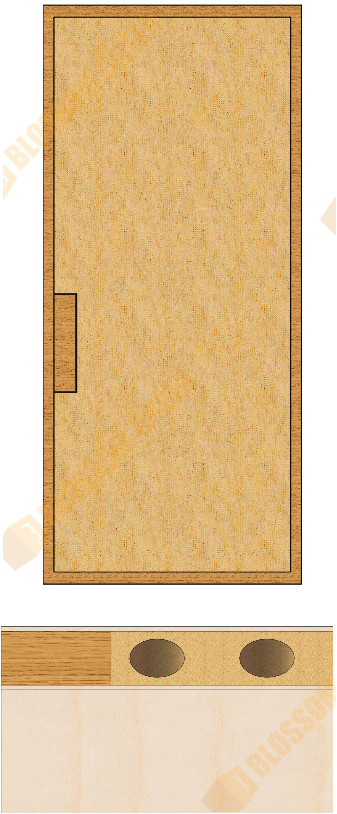

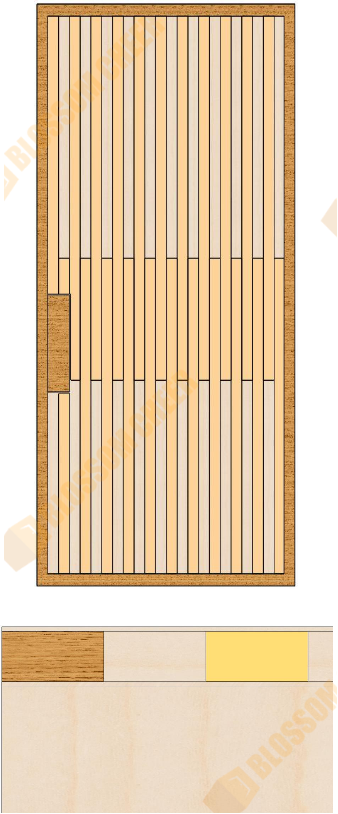

1、3

The door frame is made of plywood material, which has good waterproof performance.

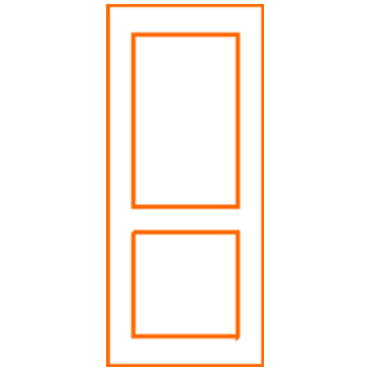

2

It is made of pressed solid wood material and belongs to the internal filling material of the door frame.

4

The part of the veneer veneer and the base material, which is consistent with the door leaf veneer process material.

5

The depth of the groove, mostly it is 15-20mm(=0.59-0.78inch) it decide how depth of the door casing (also call door architrave), it also If the wall thickness on site is thicker, you can also adjust the depth of the door casing to match the installation needs.

6

The width of the groove, it is around 5-6mm(=0.196-.236inch) width.

7

This is the area for door panel, the width is around 40-45mm(=1.57-1.77inch). As the door panel thickness can be customize, mostly with 40mm(=1.57inch), 45mm(=1.77inch), can also customize for 50mm(=1.96), 80mm(=3.14inch etc., the size can be based on the project detail needs.

8

The total thick of door frame, mostly around 33-35mm (=1.29-1.37inch), for project, we can also customize the thickness as needs.

9

The thickness of the frame area which touch with door panel, it mostly with 23-25mm(=0.9-0.98inch) thick. If the whole frame thick is customize, will influence the thickness here.

10

This is the whole frame width, it equal the wall thickness. Mostly, we customize and make the width as the real project site wall thickness, this is also the very important part but easy to ignore detail part.