Understand the needs

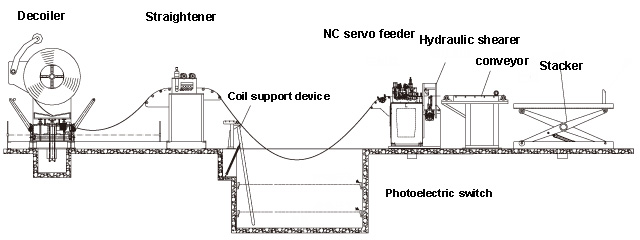

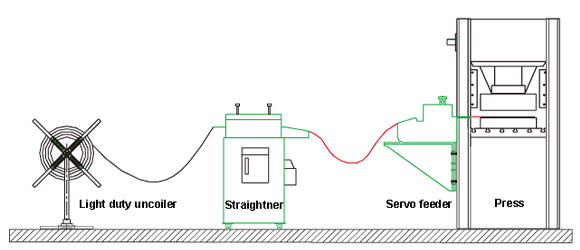

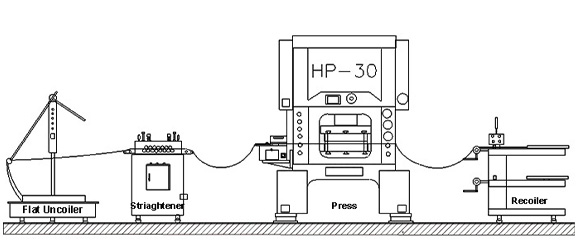

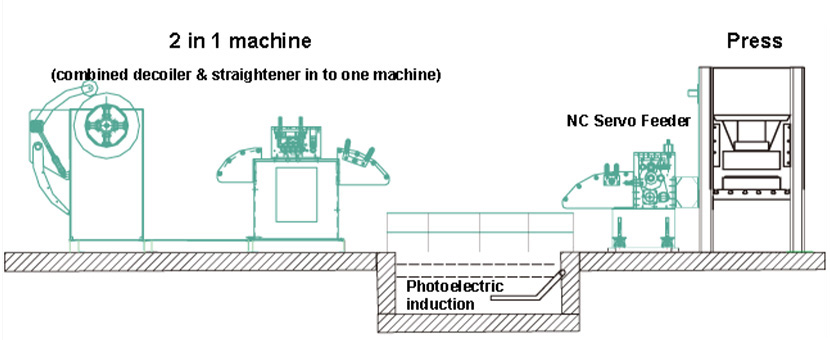

Understanding their specific needs and requirements, we formulate solutions and product solutions for different production lines.

Normally, steel process is faced with numerous challenges during factory daily operations. One of their top concerns is the safety of their employees when working with heavy equipment and in hazardous environments. They must ensure that all necessary safety measures are in place and that employees are well-trained to operate the equipment safely.

Additionally, steel mills are constantly seeking ways to cut costs without sacrificing quality or safety. They explore various cost-saving strategies, such as optimizing energy usage, reducing waste, and minimizing downtime.

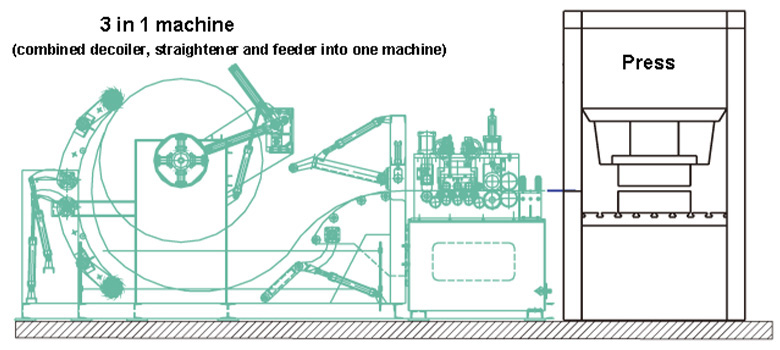

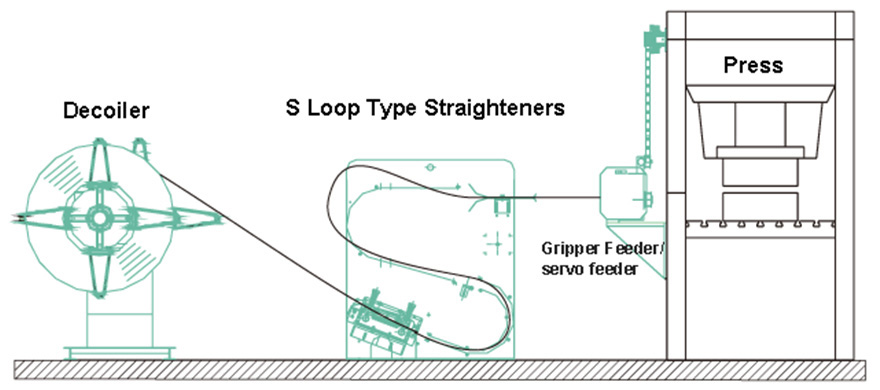

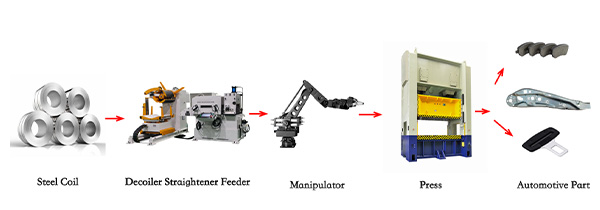

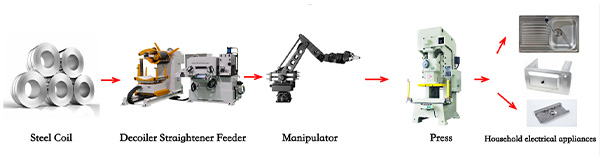

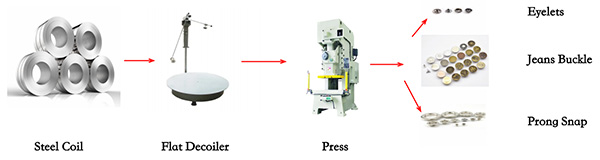

Another challenge is to improve production efficiency while maintaining high-quality standards. This requires streamlining processes and adopting new technologies to enhance productivity. Finally, steel mills must provide customized solutions to meet the unique needs of their clients. This may involve adapting their production processes to meet specific product requirements or collaborating with clients to develop tailored solutions.

Understanding their specific needs and requirements, we formulate solutions and product solutions for different production lines.

We provide cutting-edge equipment and technology that prioritizes safety, efficiency and cost savings.

By implementing these solutions, steel mills can optimize production processes, reduce waste and improve overall efficiency.

We also offer a range of product solutions tailored to meet specific customer needs.