The Ultimate Eco-Friendly Choice

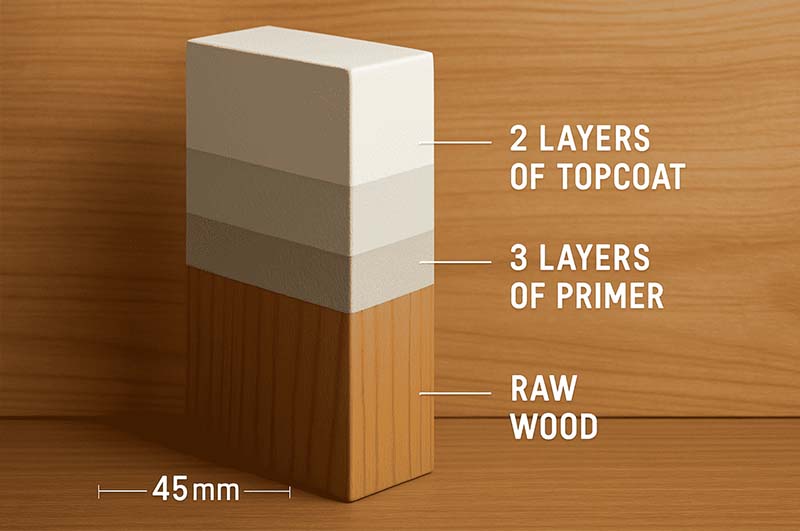

For projects prioritizing environmental responsibility and rapid deployment, our paint-free wooden doors represent the ideal solution for forward-thinking developers and builders. These doors are meticulously engineered to meet the environmental standards in North America and the European Union, proudly holding ROHS certification that guarantees compliance with the most stringent international environmental regulations.

Traditional painted doors require time for paint curing and often necessitate additional ventilation periods before spaces can be occupied. Our paint-free doors eliminate these concerns, allowing for immediate occupancy and reducing overall project completion times.

More Applicable Projects:Our paint free doors with zero formaldehyde emissions and contain no volatile organic compounds (VOCs), ensuring a healthy and safe indoor environment for all occupants. This is particularly important for sensitive applications such as schools, healthcare facilities, and residential projects where indoor air quality directly impacts occupant health and well-being.